Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The injection mold should test various properties of the mold under the normal operation of the injection molding machine and the mold, and measure the size of the final molded plastic part. Through this information, the existing state of the mold can be determined, and the cavity, core, cooling The damage of the system and the parting surface, etc., can be judged according to the information provided by the plastic parts, and the damage status and maintenance measures of the mold can be judged.

Springs and other elastic parts are most easily damaged during use, and usually break and deform. The method to take is to replace. During the replacement process, you must pay attention to the specifications and models of the springs. The specifications and models of the springs are confirmed by the three items of color, outer diameter and length, and can only be replaced when the three items are the same.

During the use of mold products, the punch is prone to breakage, bending and gnawing, and the punch sleeve is generally gnawed. Damaged punches and sleeves are generally replaced with parts of the same specification. The parameters of the punch mainly include working part size, installation part size, length size, etc.

Parts also need to be fixed from time to time. It is necessary to check whether the fastening parts are loose or damaged. The method is to find parts of the same specification for replacement.

During maintenance, check the relationship between the parts and whether there is any damage, repair the damaged parts, check whether there is air leakage with the pneumatic jacking material, and take measures for the specific situation. If the trachea is damaged, replace it.

It is necessary to focus on tracking and testing of several important parts of the mold: the function of ejection and guide parts is to ensure the opening and closing movement of the mold and the ejection of plastic parts. If any part of them is stuck due to damage, it will lead to production stoppage, so it should be kept Lubricate the mold thimble and guide post (the most suitable lubricant should be selected), and regularly check whether the thimble and guide post are deformed and surface damaged. Once found, they should be replaced in time.

After completing a production cycle, professional anti-rust oil should be applied to the working surface, motion and guide parts of the mold, and special attention should be paid to the protection of the elastic strength of the bearing parts with gears, rack molds and spring molds to ensure that they are always in top working condition.

At the same time, attention should be paid to the cleaning of the runner, because the longer the time is, the more scale, rust, silt and algae will be deposited in the cooling channel, which makes the section of the cooling channel smaller and the cooling channel narrower, which greatly reduces the heat exchange between the cooling liquid and the mold. rate and increase the production cost of the enterprise. For hot runner mold products, maintenance of heating and control systems is beneficial to prevent production failures.

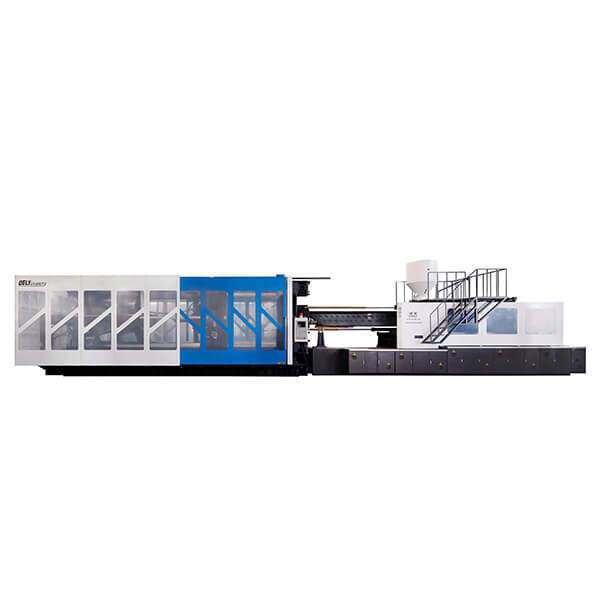

Main Features:

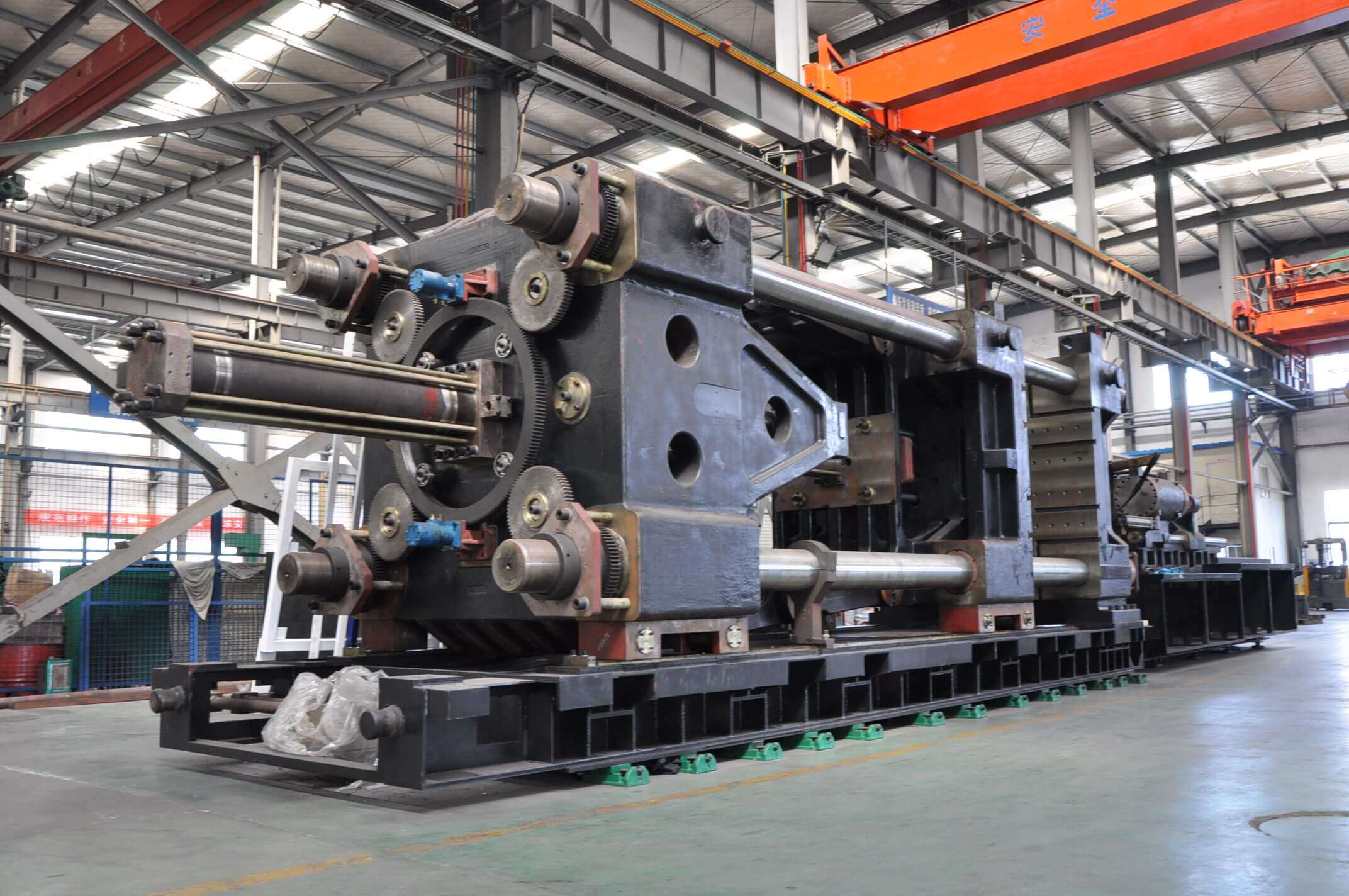

One.The Lock Section

1.Arch template, effectively protects the mould, especially suitable for big template with small mold.

2.The electric ruler is installed on the crosshead, the position is more precise.

3.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly

4.The connected tail-board stills itself with big lock shaft, improves tail-board strength, and ensures zero abrasion of the tail-board, easy for maintenance.

5.Connected movable plate, improves its rigidity and reduces deformation

6.Connected thrust bearing, improves its strength and stills itself with small lock shaft, ensures zero abrasion.

7.Arch template fully complies with mechanical property, largely improves template strength.

8.More reasonable toggle design, speeds and stabilizes mold opening and closing.

9.Adjustable movable plate mounting plate, makes the installation easier.

10.Mixed design of T-shape groove and die hole, increases universality of the mold.

Two.The Injection Section.

1.Bridge type support, improves injection smoothness.

2.Longer length-diameter ratio screw design, improves plasticizing effect.

3.Double seal structure, ensures no oil leakage.

4.Withhold type press plate, easy for debugging and assembly.

5.Bijection structure, improves stability.